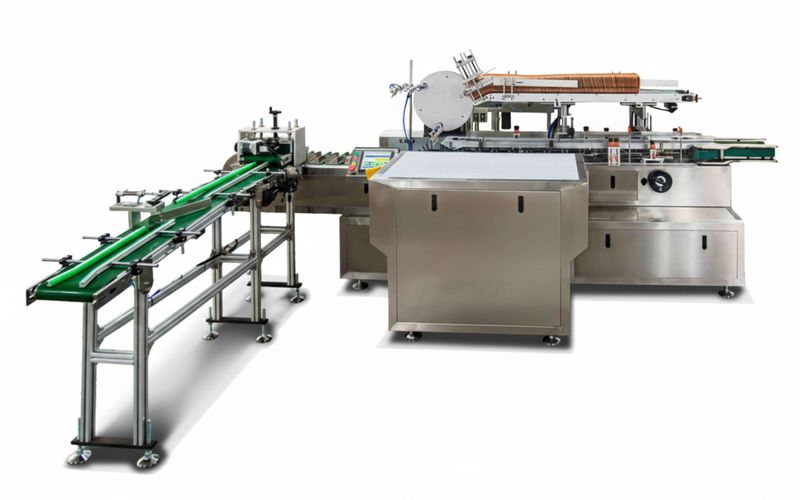

Machine Type: Rotary Automatic Machine (Carousel)

Purpose: Automatic picking, opening, filling, and sealing of premade pouches (doypack, sachet, flat pouch).

1. General Description

High-efficiency rotary machine designed to handle a wide range of premade pouches. The device is characterized by precision, easy changeover for different pouch formats, and the ability to integrate with any dosing system. An ideal solution for manufacturers focusing on packaging aesthetics (premium look) and production flexibility.

2. Application (Industries and Products)

Thanks to the modular design of the dispensers, the machine handles:

- Granules and Solid Products: Coffee, tea, rice, nuts, dried fruits, chips, pet food, seeds.

- Powders: Milk powder, flour, spices, supplements, detergents.

- Liquids and Pastes: Sauces, ketchups, juices, liquid soaps, creams.

- Piece Products: Candies, frozen foods, cookies.

3. Supported Pouch Types

The machine works with premade pouches, guaranteeing the highest visual quality of the packaging:

- Doypack (Stand-up pouch).

- Zipper pouches.

- Flat pouches (3-side or 4-side sealed).

- Gusset bags.

- Shaped pouches (irregular shapes).

4. Main Features and Benefits

- Intelligent Control System (No Bag - No Fill): If a pouch is not picked or opened, the machine will not dispense the product or seal. Saves product and packaging.

- Quick Changeover: Pouch format change is done via a single knob or HMI panel (gripper adjustment), taking only a few minutes.

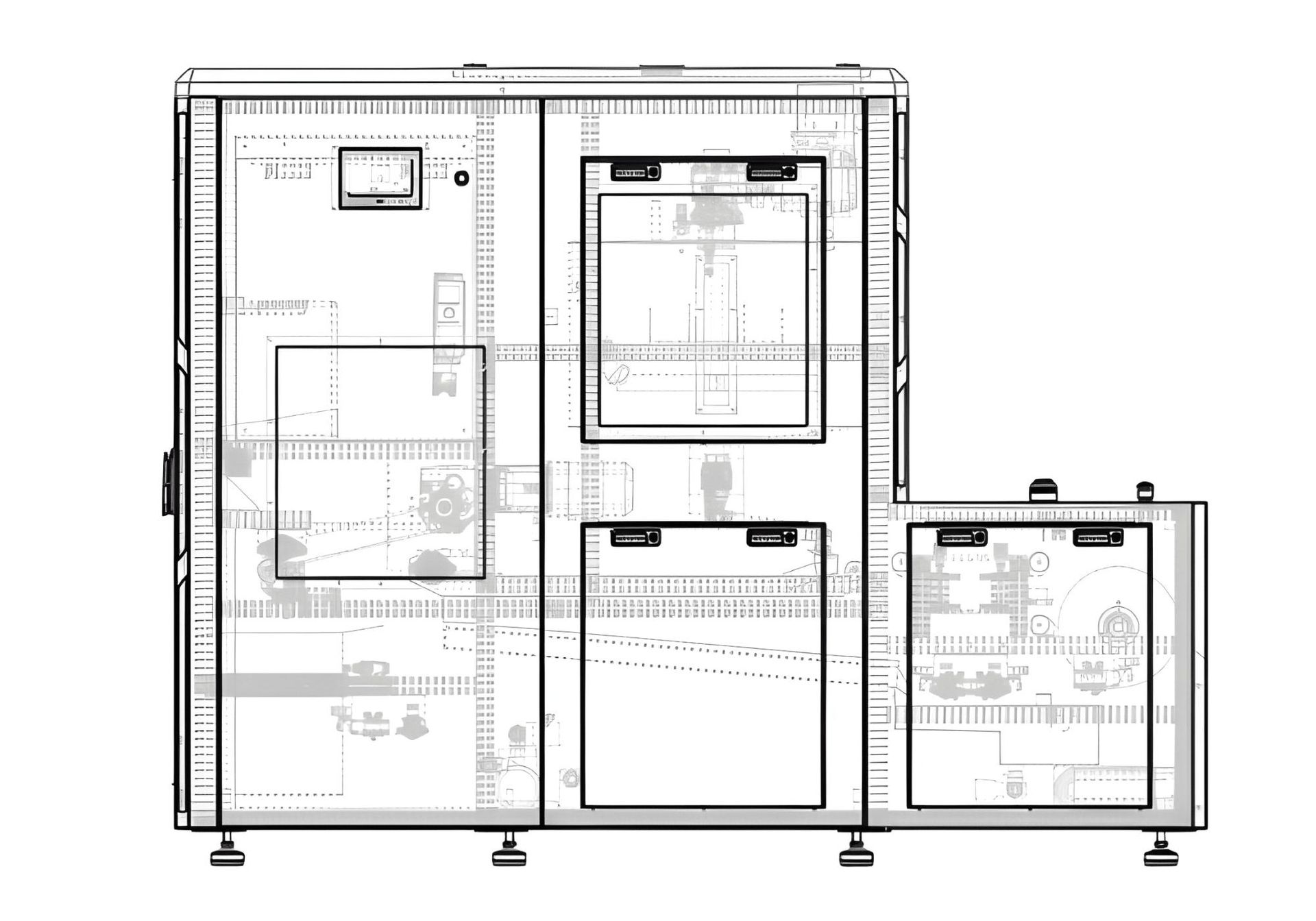

- PLC and HMI Control: Intuitive touch screen (Siemens/Mitsubishi) allows easy management of operating parameters.

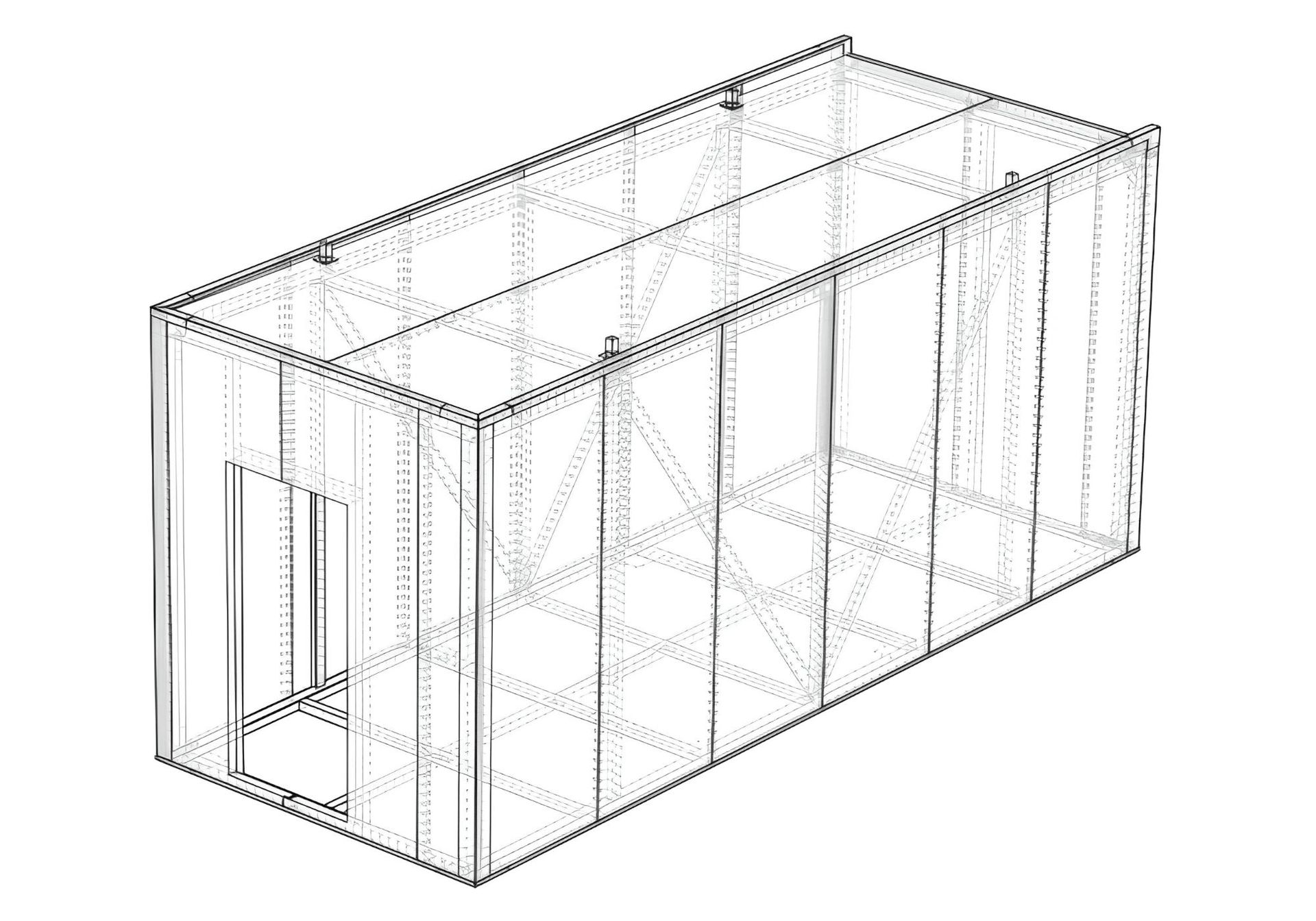

- Hygiene: Construction made of stainless steel (AISI 304/316) according to GMP standards. Easy to clean (Wash-down).

- Lubrication System: Central lubrication system (optional) or maintenance-free bearings (IGUS) at key points.

5. Technical Specification

| Parameter |

RZ8 Series (Standard) |

RZ10 Series (High Speed) |

Heavy Duty Series (Large Bags) |

| Number of Stations |

8 stations |

10 stations |

8 stations |

| Pouch Width |

80 – 240 mm |

60 – 220 mm |

150 – 370 mm (up to 400 mm) |

| Pouch Length |

100 – 350 mm |

80 – 300 mm |

100 – 500 mm |

| Dosing Range |

10g – 1500g |

10g – 1000g |

500g – 5000g |

| Speed (max) |

up to 60 pouches/min |

up to 80-100 pouches/min |

up to 30-40 pouches/min |

| Power Supply |

380V / 50Hz / 3Ph |

380V / 50Hz / 3Ph |

380V / 50Hz / 3Ph |

| Air Consumption |

0.5 m³/min |

0.5 m³/min |

0.7 m³/min |

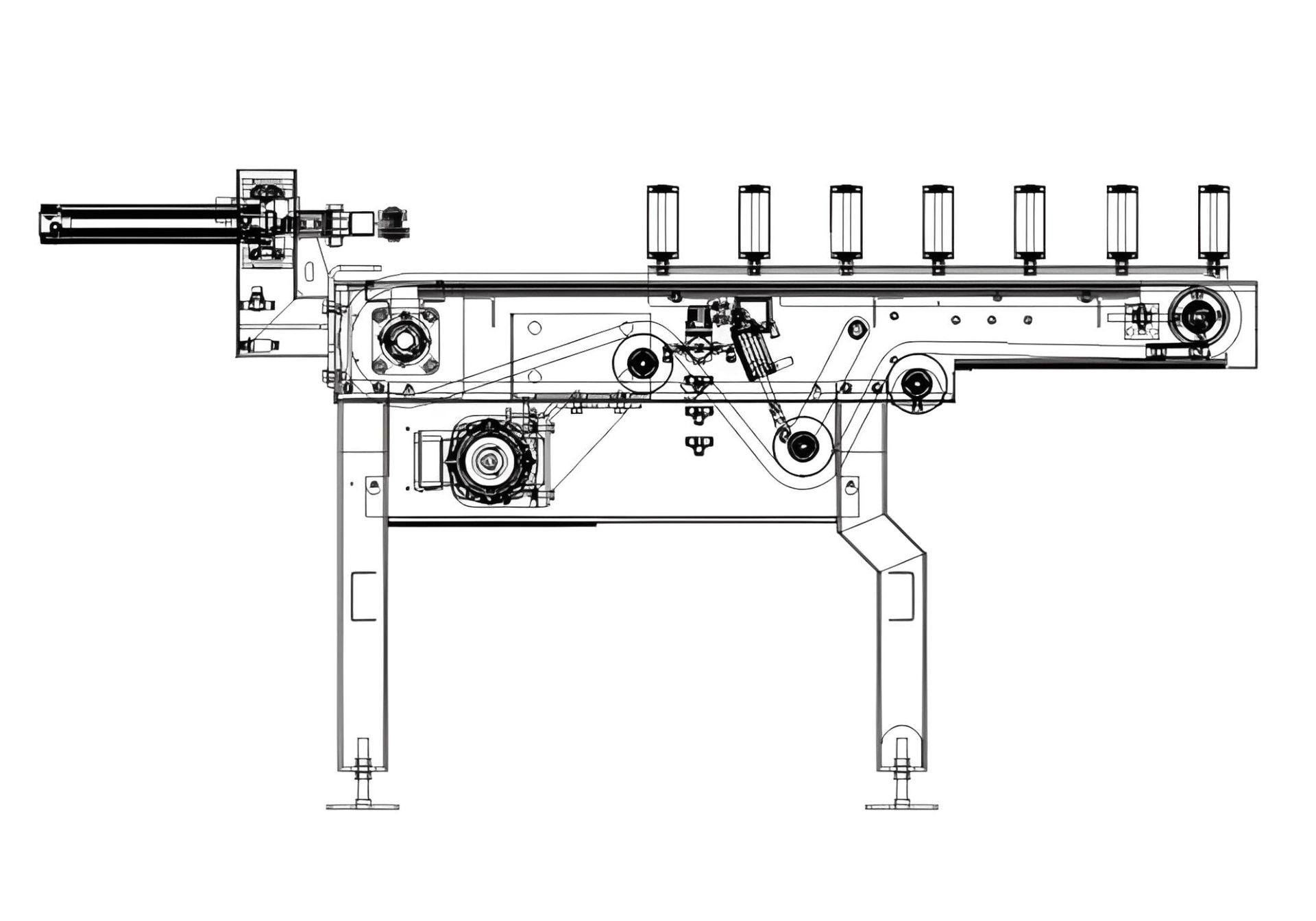

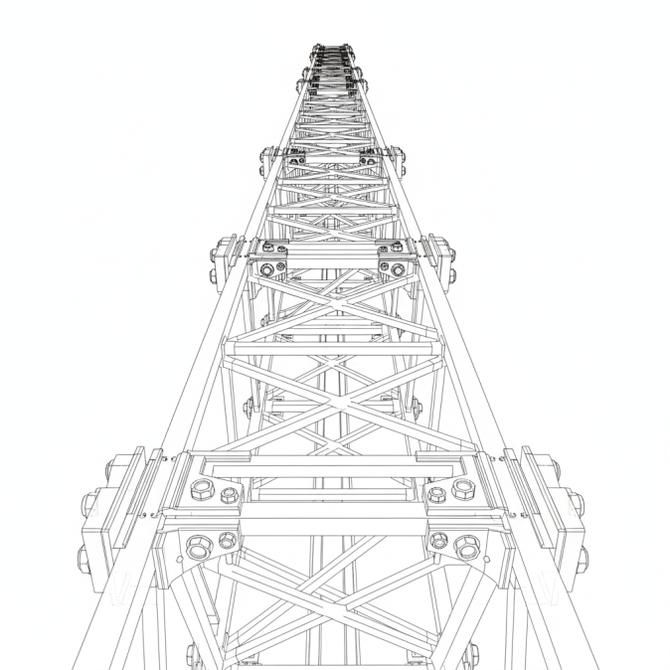

6. Packaging Process Flow (8 Stations)

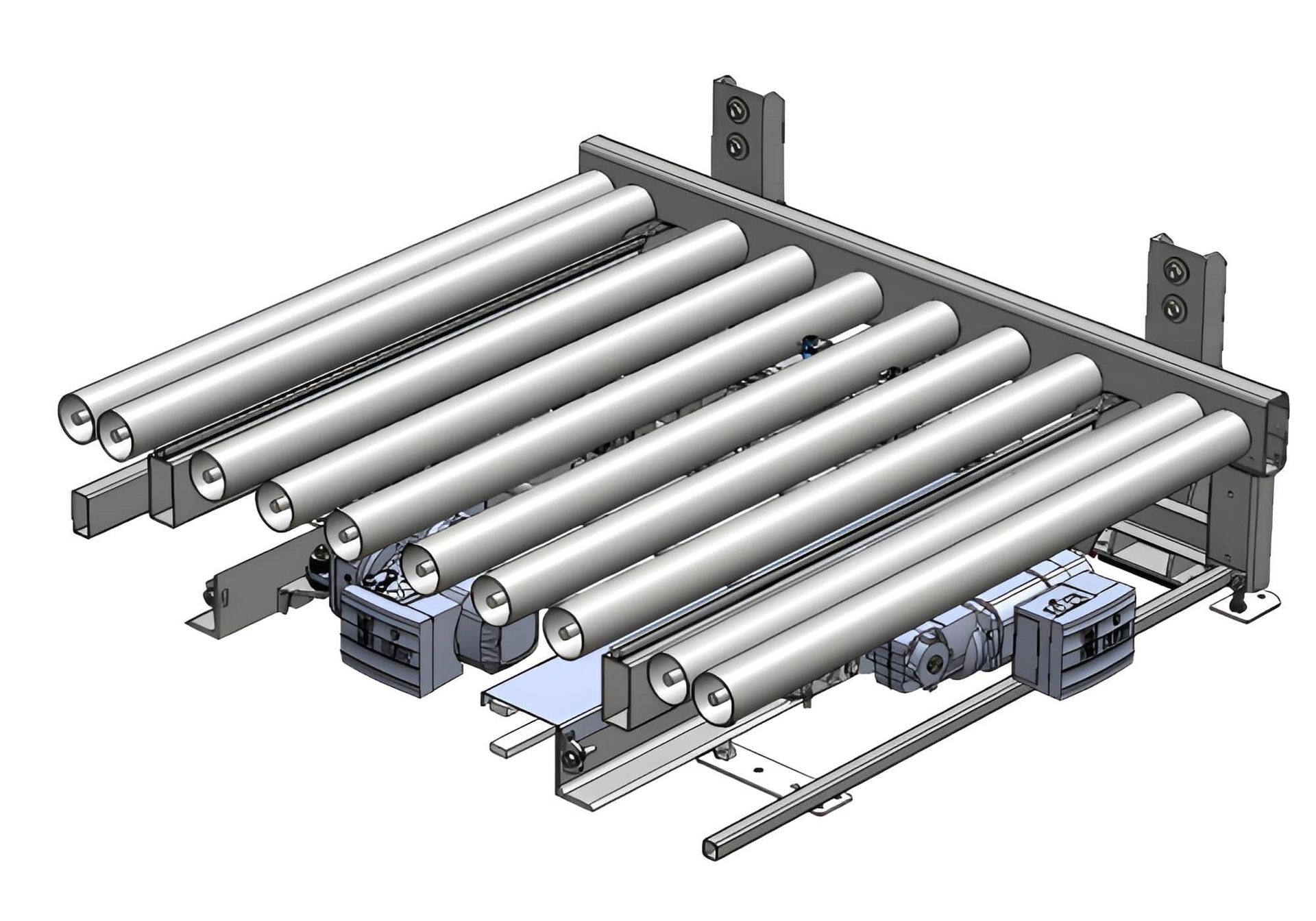

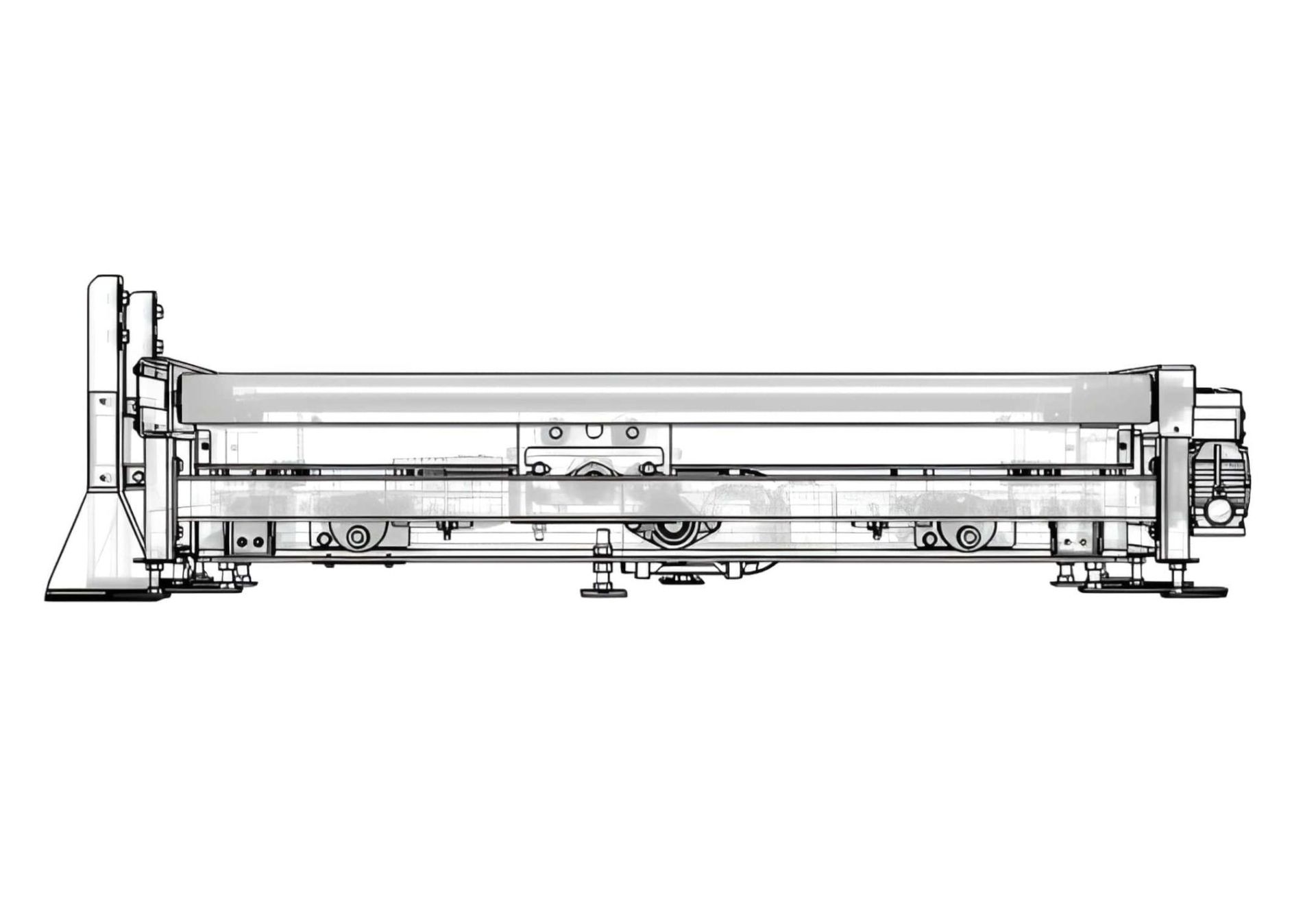

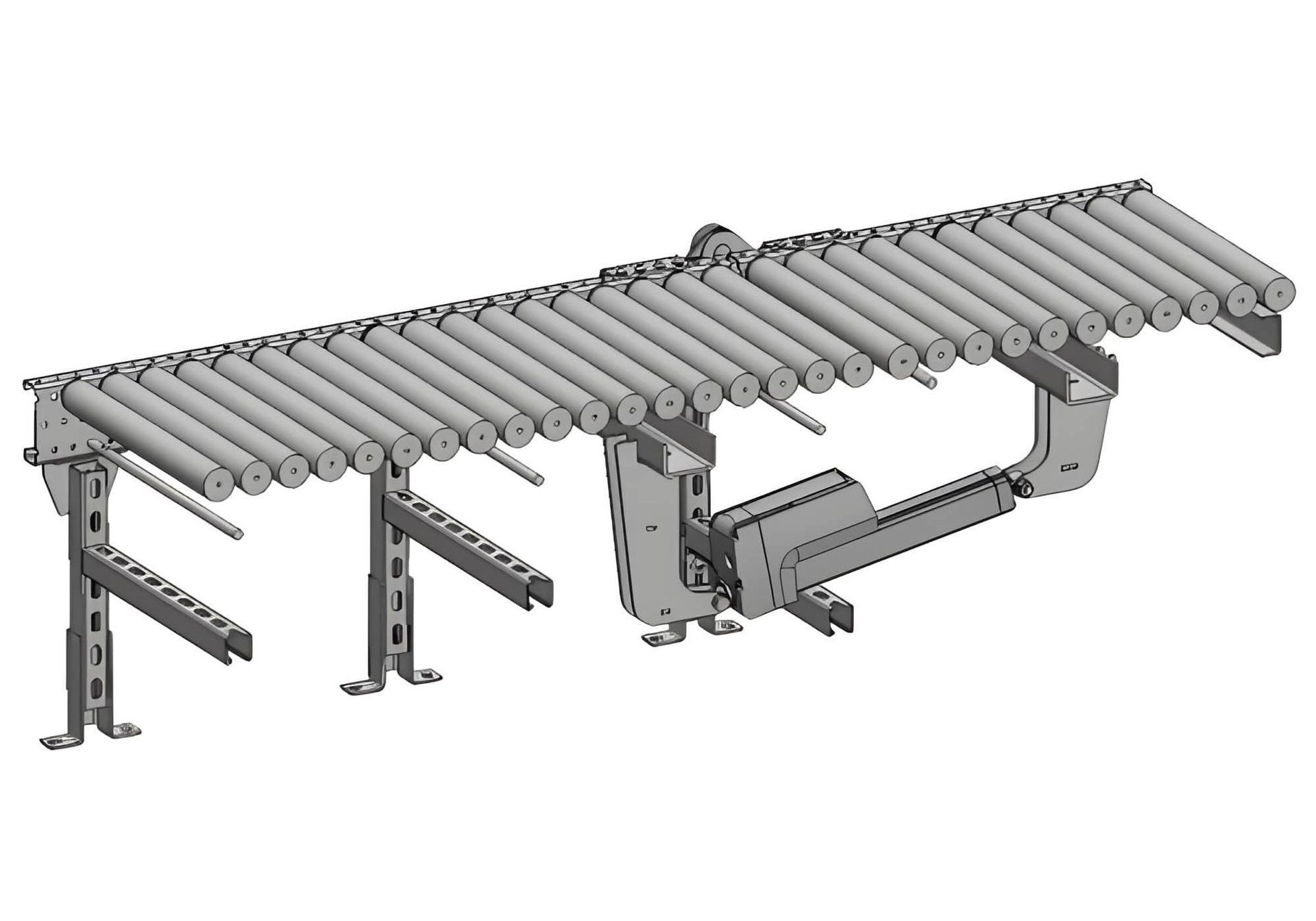

- Pouch Picking: Magazine automatically feeds the pouch to the grippers.

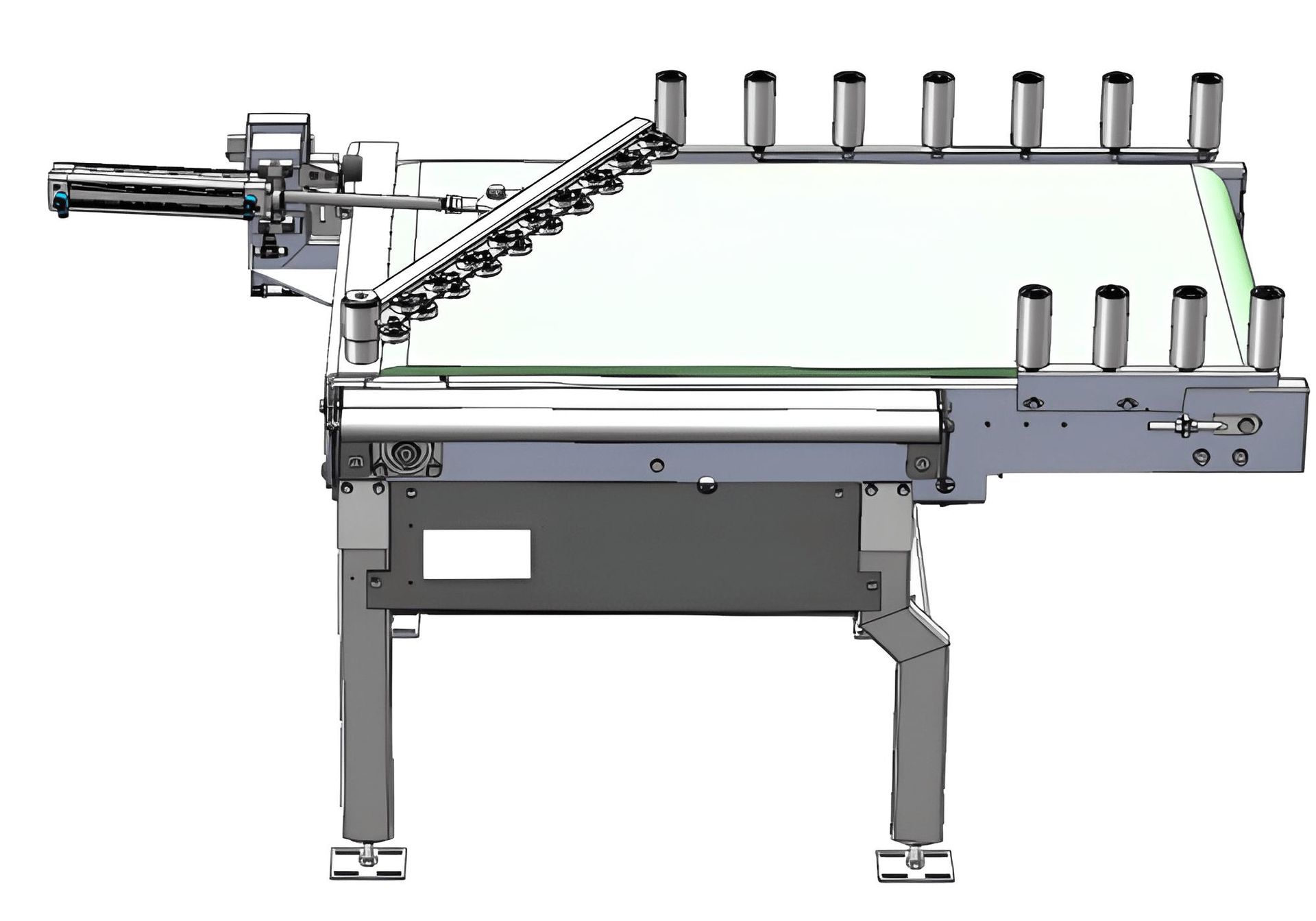

- Coding: Date/batch printing (Inkjet, thermal transfer).

- Opening: Opening the pouch (and zipper) using suction cups and air blow.

- Dosing 1: Main product filling (e.g., from multihead weigher).

- Dosing 2 / Option: Top-up, adding liquid, or vibration station (product settling).

- Cleaning / Suction: Dust removal from seal area or nitrogen option (MAP).

- Sealing: Thermal sealing of the package.

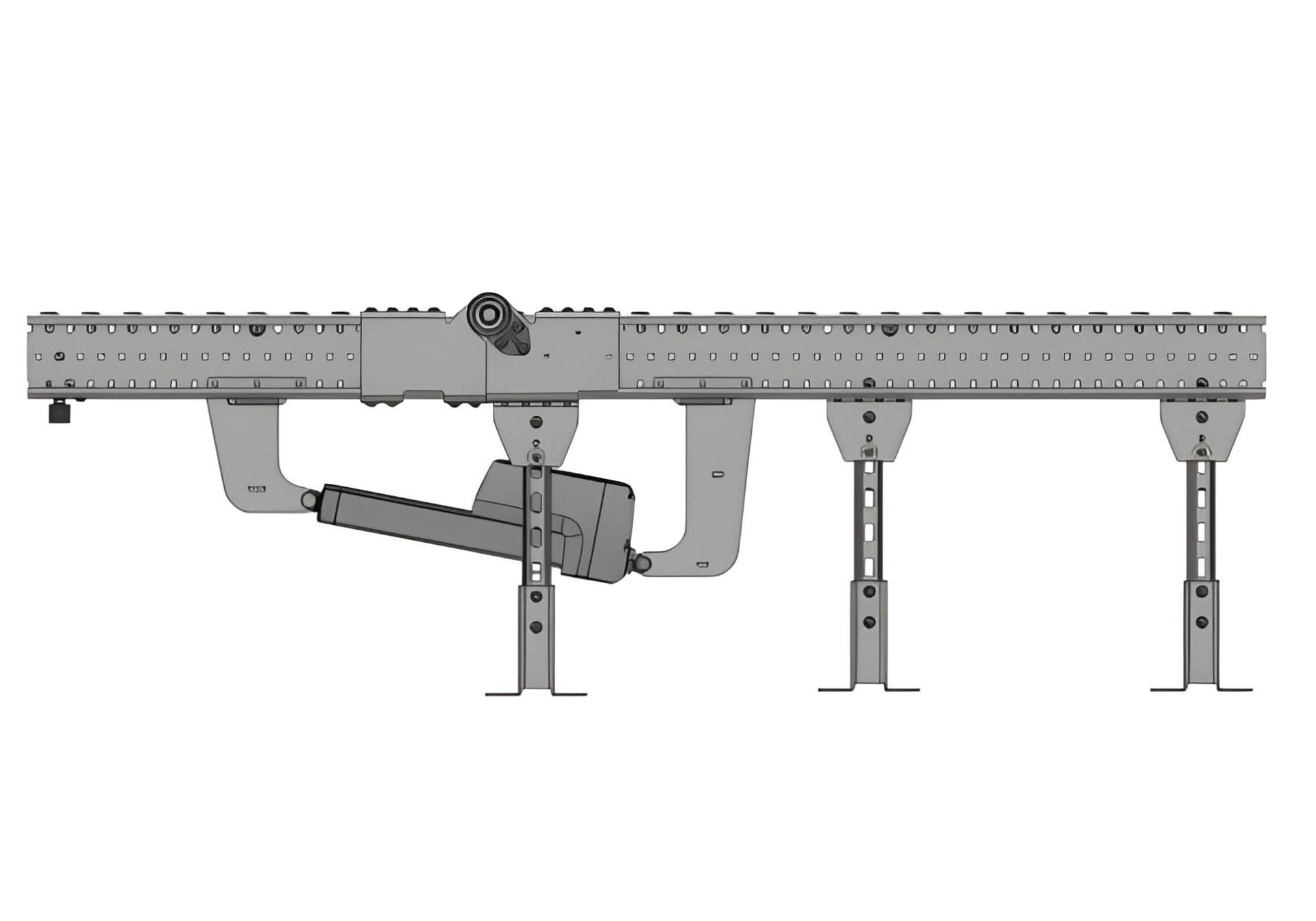

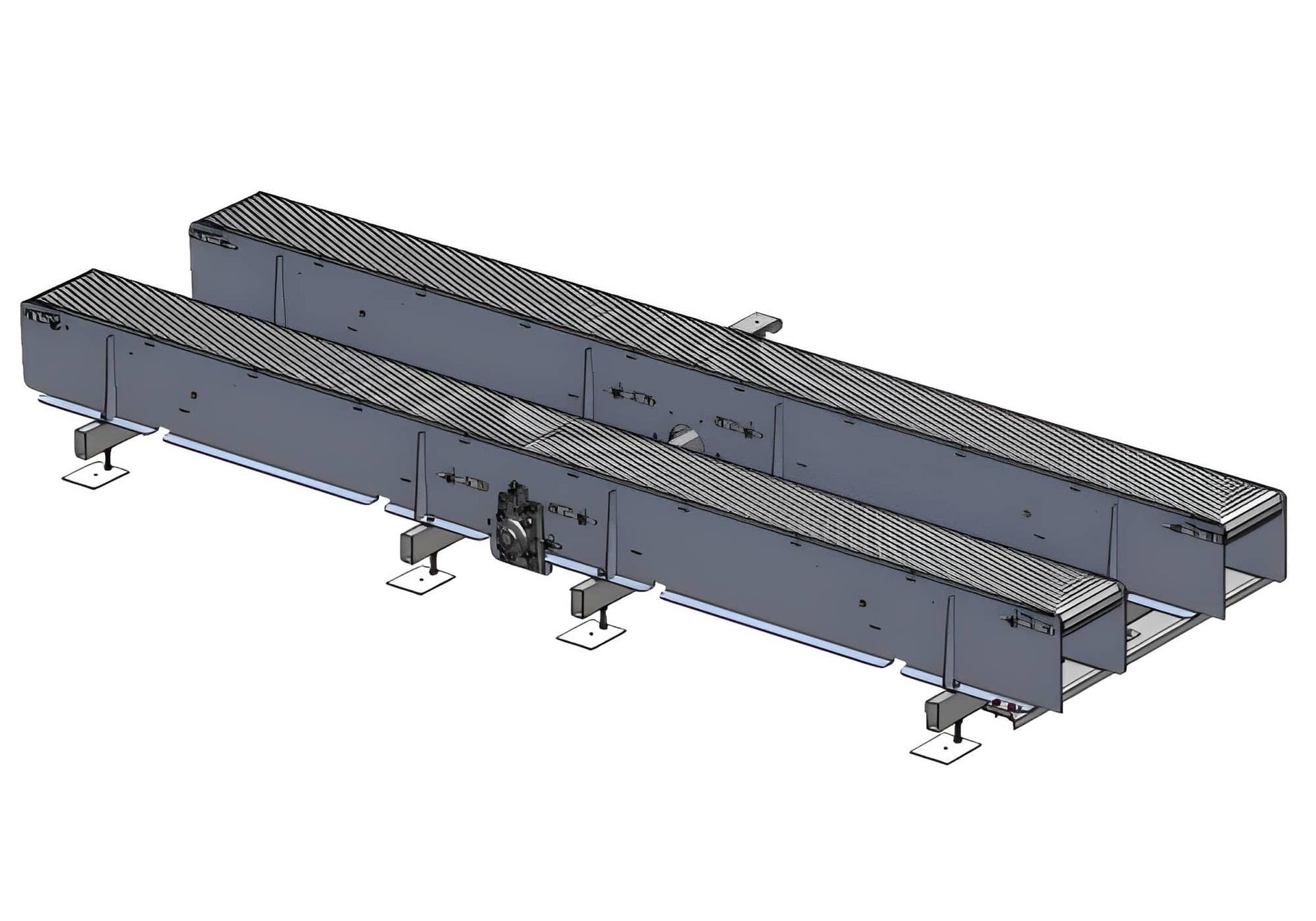

- Forming and Discharge: Seal cooling and discharge of finished product to conveyor.

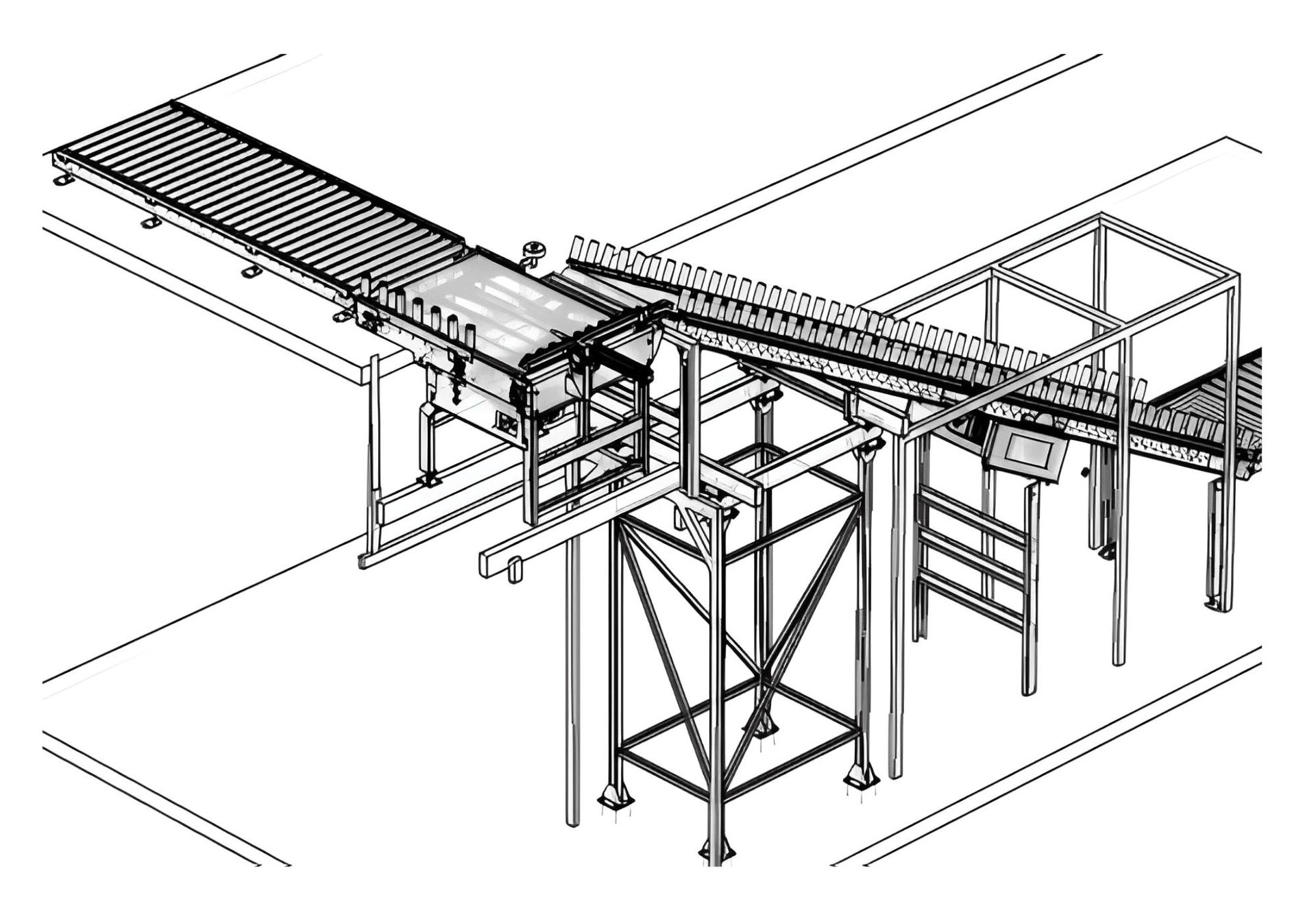

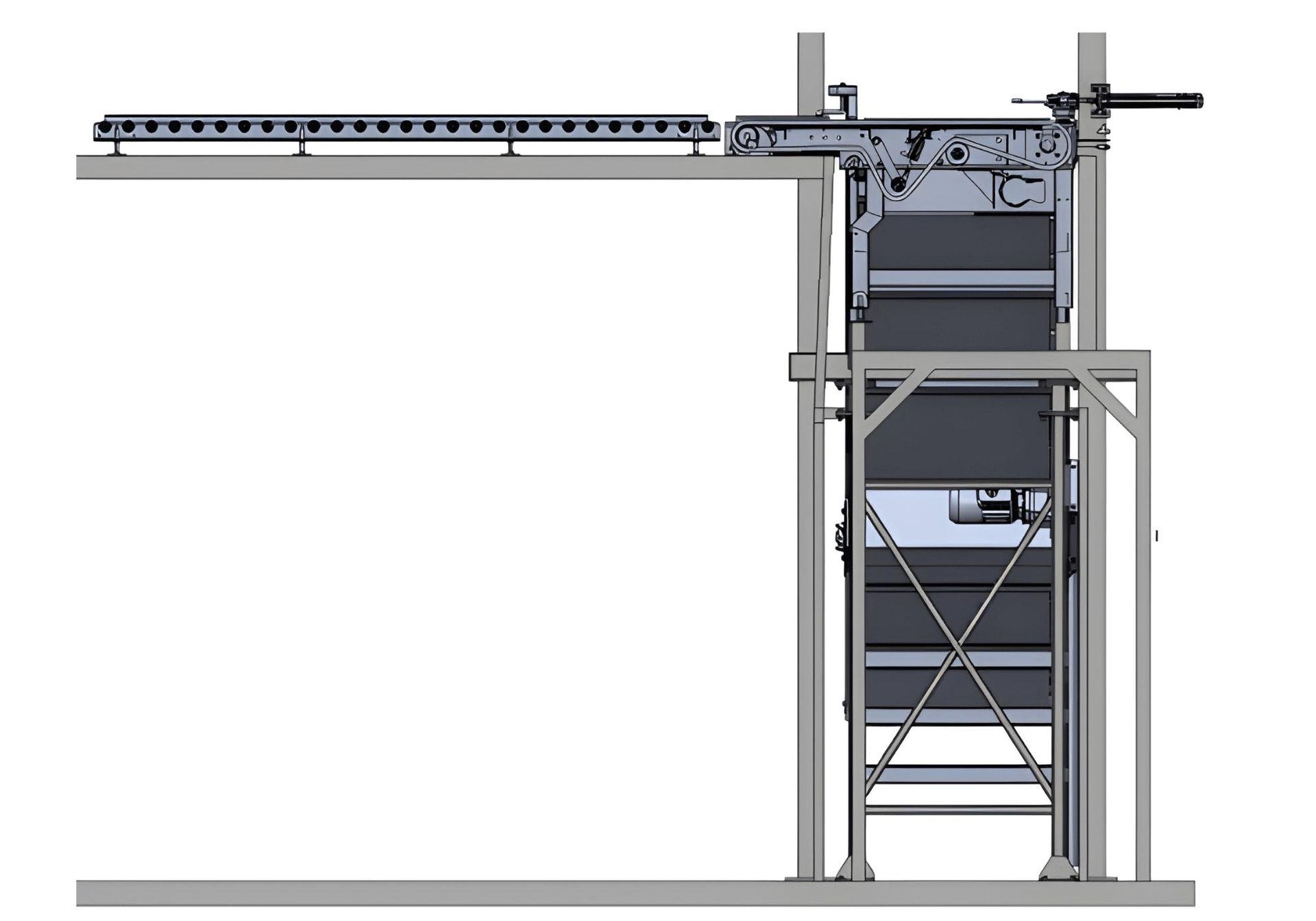

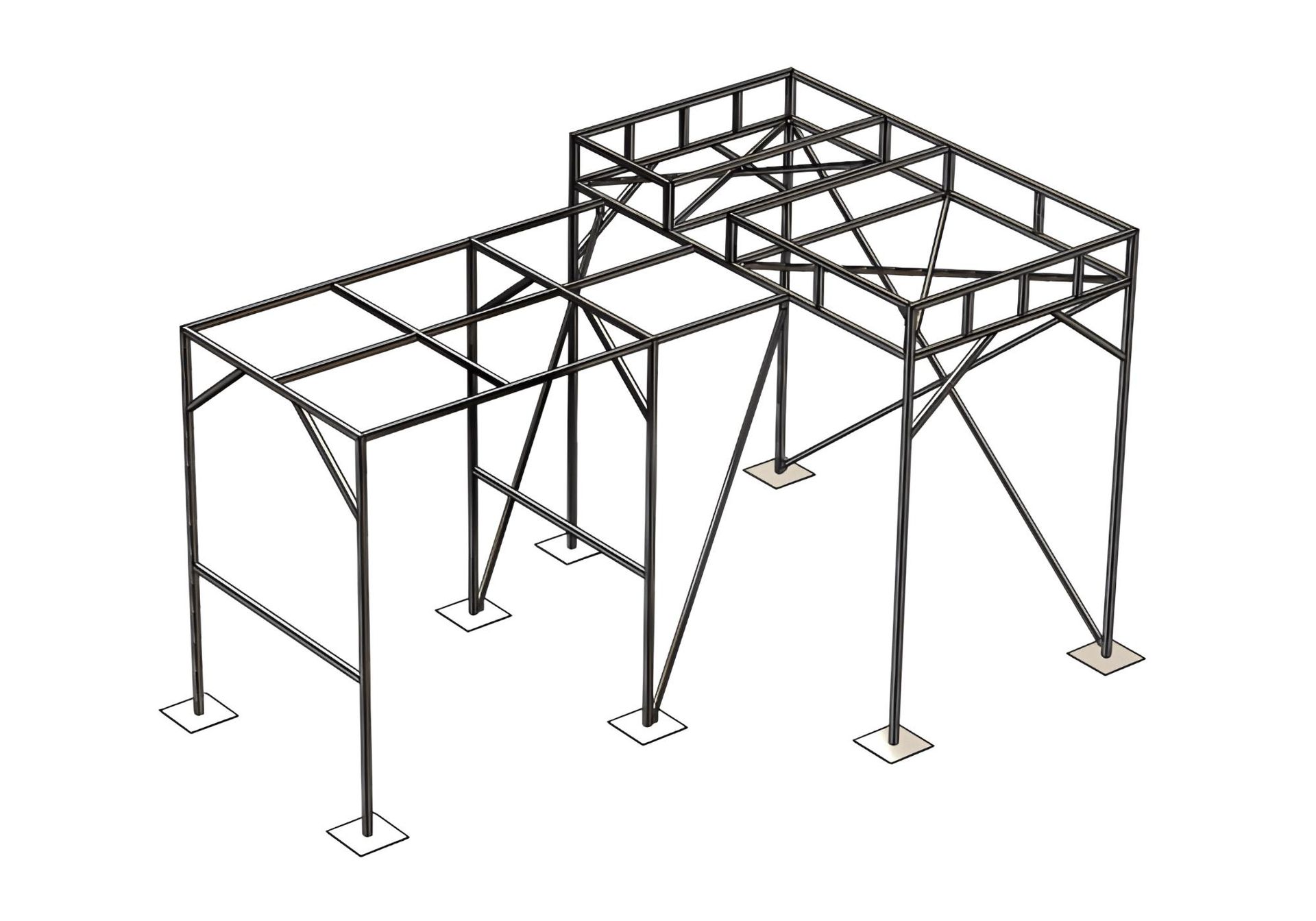

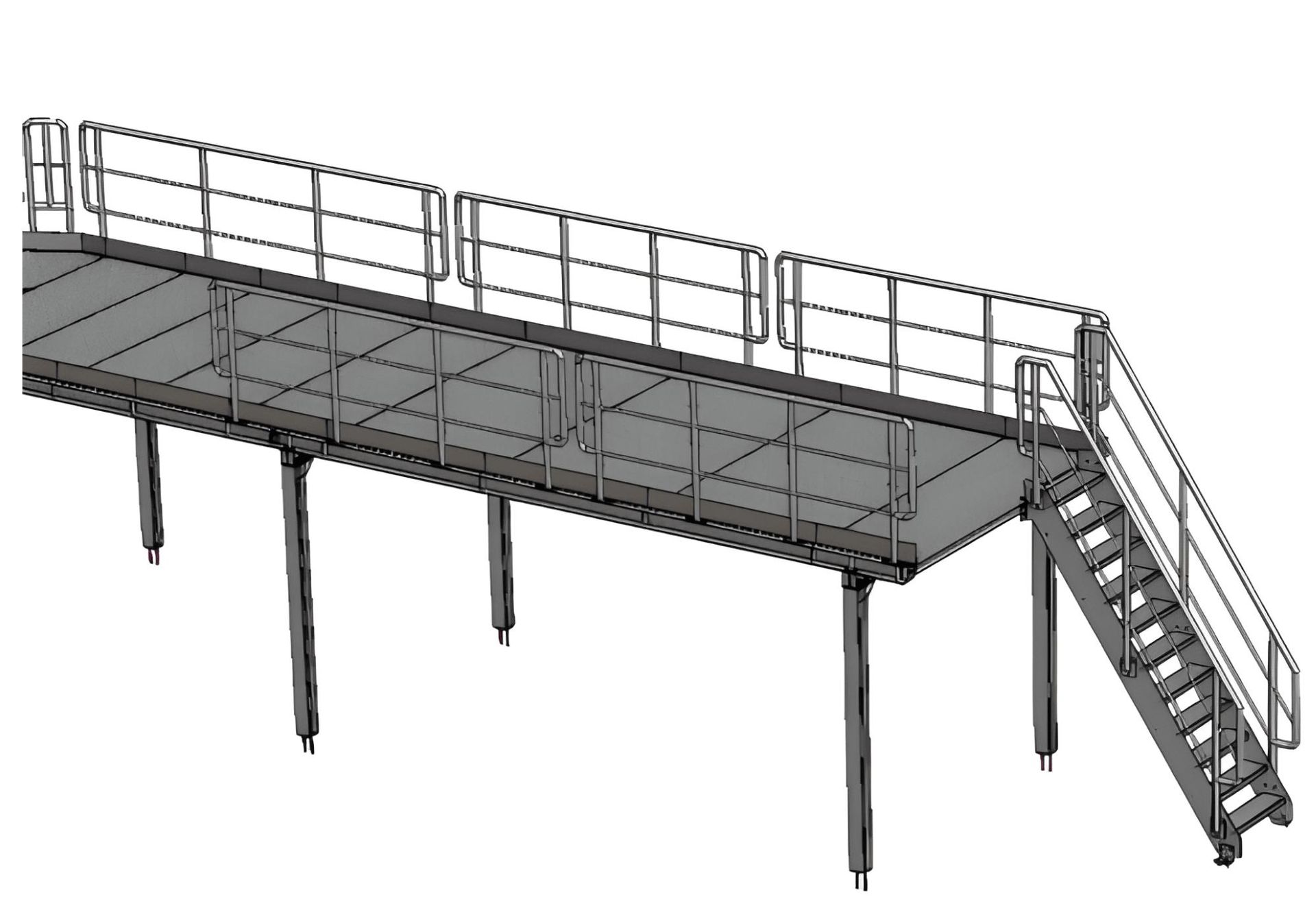

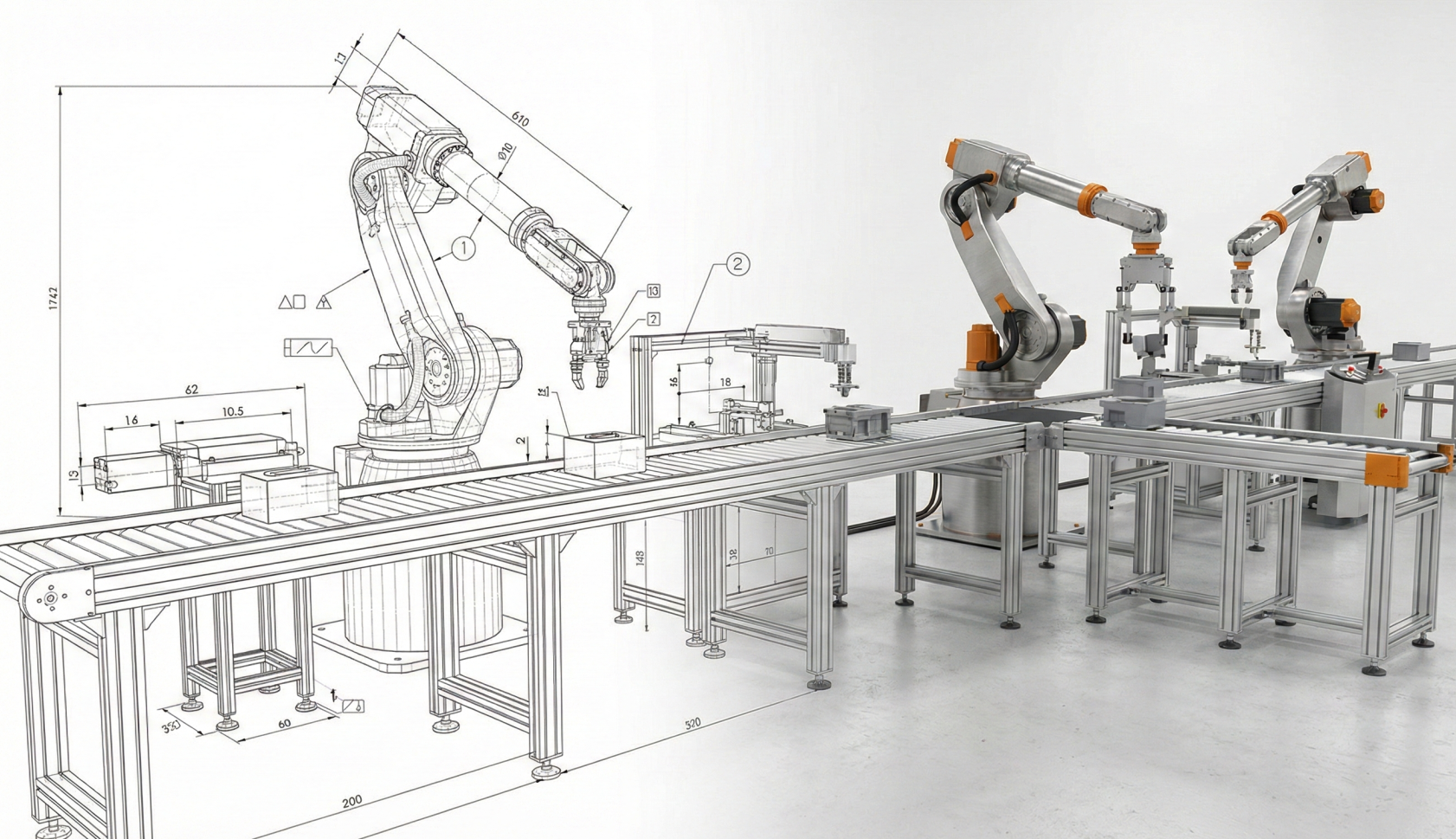

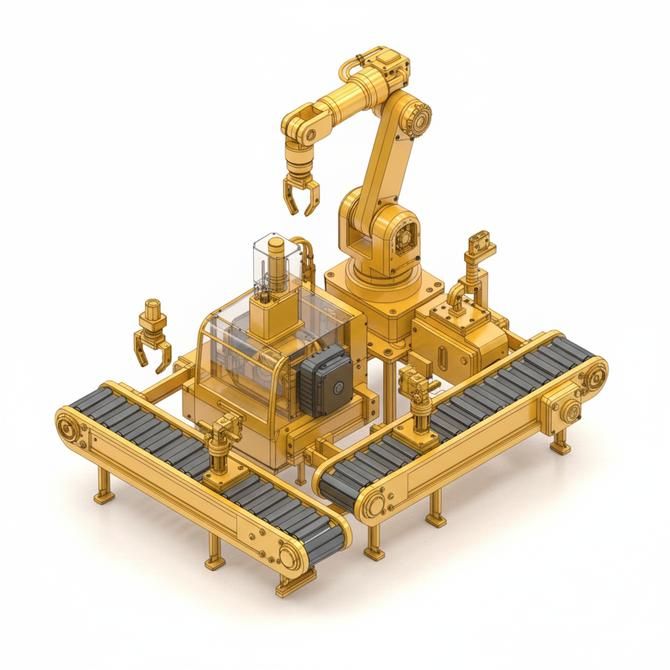

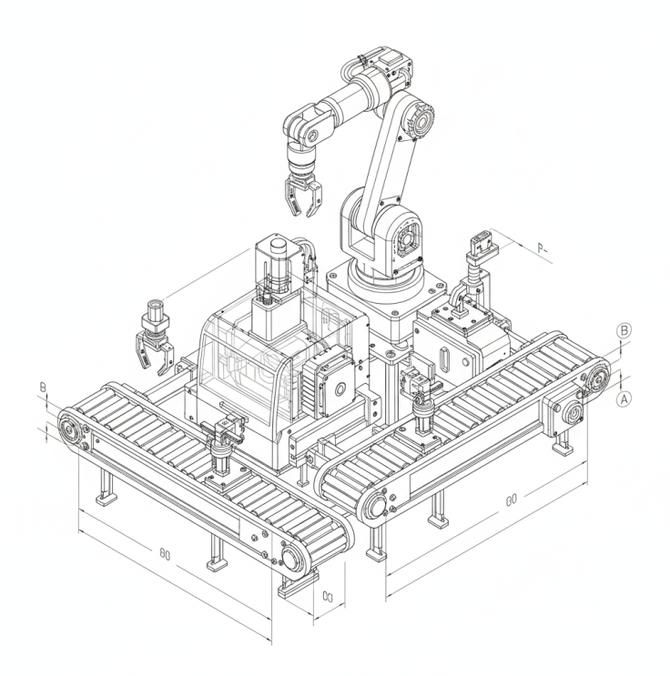

7. Integration into Production Lines (SKE Design)

As a system integrator, we combine this machine with peripheral devices to create complete lines:

- Weighing Systems: Multihead Weighers, linear weighers, auger fillers.

- Feeding Systems: Z-type bucket elevators, screw conveyors, pumps.

- Quality Control: Checkweighers, metal detectors, X-Ray systems.

- End of Line: Automatic cartoners and palletizing systems.